Why Laser Engraving Beats Traditional Engraving for Trophies in Sydney

Recognition matters. Whether it’s a student receiving an academic award, a football team lifting a championship cup, or a company celebrating years of service, the trophy itself becomes a permanent symbol of achievement. What makes a trophy memorable is the engraving — the crisp name, the reproduced logo, the date that tells a story. Increasingly, event organisers, schools, and businesses in New South Wales are choosing laser engraved trophies Sydney because laser work delivers consistent quality, excellent detail, and fast turnarounds that traditional techniques struggle to match.

This guide explains how laser engraving works, why it outperforms rotary, chemical, and printing-based methods for most trophy work, which materials it suits best, and practical tips for getting the best results for your event in Sydney.

What is laser engraving, and how does it work?

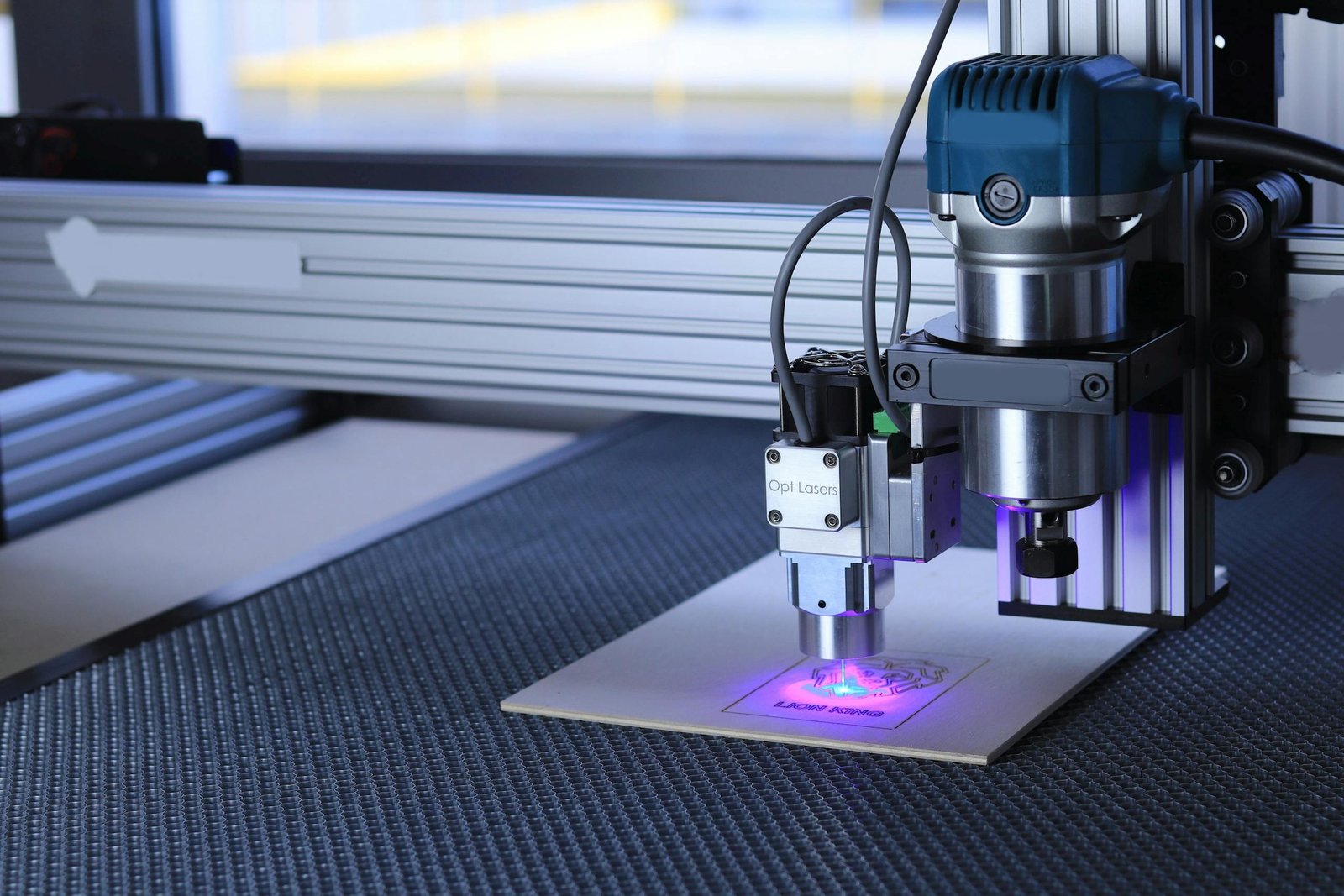

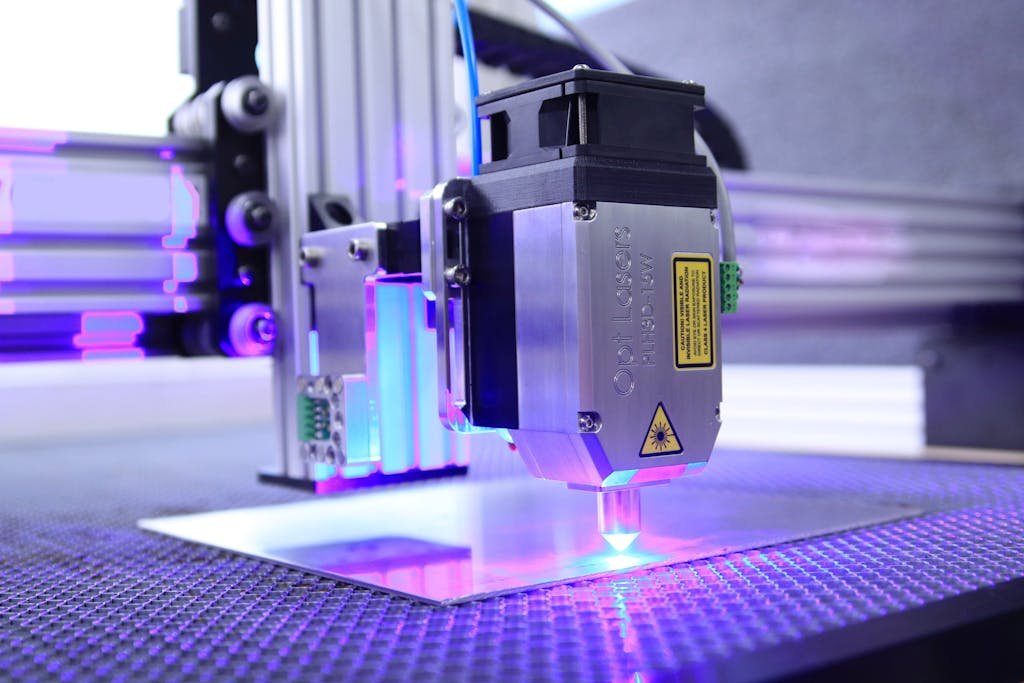

Laser engraving uses a focused beam of light to vaporise, ablate or modify the surface of a material according to a digital design. Artwork is prepared in vector or high-resolution raster formats, converted to machine instructions, and executed by a CNC-style laser head. Because the process is contactless, lasers leave clean edges and precise detail without mechanical chatter or tool wear.

Two laser families are commonly used in trophy work: CO₂ lasers for non-metallic substrates (acrylic, timber, glass, crystal) and fibre lasers for metals (stainless steel, brass, anodised aluminium). Many Sydney suppliers run both systems, so a single workshop can handle panels, plates, and bases in one job, which is one reason buyers searching for laser engraved trophies Sydney get comprehensive, single-source service.

Traditional engraving techniques — a quick overview

Before lasers were widely available, award shops used methods such as:

- Rotary engraving: A cutting bit physically carves the surface. Suitable for heavy-duty plates but limited in minute detail and photo-like reproduction.

- Chemical etching: Uses masks and acid baths to remove material. It can be detailed, but it comes with hazardous consumables and a lengthy setup process.

- Sublimation and direct printing: Add colour and photographic elements, but do not produce a permanent, tactile engraved mark.

All these methods have valid use cases, but they tend to require more setup, more consumables, and more manual finishing than laser workflows. For many modern requirements — especially on mixed-material trophies and fast-turnaround orders — laser is simply more practical.

Quick comparison: laser vs traditional

| Feature | Laser engraving | Traditional techniques |

| Turnaround | Fast — digital proofing and immediate production | Often slower — masks, plates, or tooling required |

| Detail | Micron-level accuracy for logos and photos | Limited by cutting tools or chemical processes |

| Material range | Wide: acrylic, glass, timber, crystal, metals | Often method-specific |

| Per-unit cost (bulk) | Lower after capital investment | Higher due to consumables & tooling |

| Environmental impact | Low (no inks/chemical baths) | Higher in etching/printing processes |

This practical advantage is exactly why event planners searching for laser engraved trophies Sydney repeatedly pick laser suppliers for school awards, corporate programs, and sports finals.

Why Sydney buyers favour laser-engraved trophies

Sydney’s award calendar is busy: school prize-givings, sporting finals, corporate recognition events, and community awards all compete for time. Laser engraving answers the key local needs:

- Speed and reliability: Short runs and quick proofs meet tight timelines.

- Consistency for bulk orders: Identical results across dozens or hundreds of pieces.

- Precision: Crisp logos and small text preserve brand identity.

- Local service: The ability to proof, inspect a sample, and collect locally is a decisive benefit when ordering laser engraved trophies Sydney.

Those practical benefits explain why procurement teams and event managers often begin their vendor searches with the exact phrase laser engraved trophies Sydney.

Best materials for laser-engraved awards

Acrylic and glass

Acrylic looks modern and is cost-effective. CO₂ laser etching produces a frosted, contrast-rich finish that photographs well and shines under stage lighting. Glass and crystal yield a premium optic; laser marks on crystal can appear as internal frosted etching for a refined, executive look.

Timber and wooden plaques

Wood has warmth and tradition. Laser marking follows the grain, producing deep, high-contrast results without the need for separate metal plates. Timber shields and mounts remain a favourite for community awards and school prizes.

Metals and nameplates

Fibre lasers produce permanent, high-clarity marks on stainless steel, brass and anodised aluminium. Perpetual trophy plates and engraved badges benefit from this durability and resistance to polishing wear, which is why many long-term recognition fixtures use laser-engraved plates.

Hybrid designs

Combining materials — an acrylic panel on a timber base with a metal plate, for example — allows designers to mix tactile finishes. Laser workflows unify these components with consistent marks, which makes laser engraved trophies Sydney attractive for bespoke, high-end projects.

Sustainability and responsible sourcing

Laser engraving has sustainability advantages. It avoids inks, solvents, and chemical etching baths, resulting in lower hazardous waste generation. Many suppliers offer recycled acrylics and responsibly sourced timber, allowing buyers to select eco-friendly laser engraved trophies Sydney that align with corporate sustainability policies or school procurement requirements.

Designing for laser: artwork and file prep

To get the best engraving results, follow these rules:

- Supply vector files (AI, EPS, SVG, PDF with outlines) for logos and text.

- Convert fonts to outlines to avoid mismatches.

- Use bold, simple typefaces for small-size text; hairline scripts often lose legibility.

- For photo engraving, supply high-resolution images and request a test proof.

- Allow margins on small trophies to prevent clipped text.

Organisations that frequently order laser-engraved trophies in Sydney often maintain a folder of approved, pre-checked artwork to speed reorders and keep branding consistent.

Production workflow and quality control

A typical, reliable process looks like this: briefing → artwork submission → digital proof → sample run (recommended for new designs) → production → inspection → delivery. Because lasers are digitally driven, changes are fast and cost-efficient compared with building plates or masks. Quality checks focus on contrast on different materials, logo fidelity, and accurate serialisation where required.

Turnaround, logistics, and lead times in Sydney

Lead times depend on material and volume. Typical windows:

- Simple acrylic trophies: 24–72 hours (small runs).

- Metal plates and multi-material trophies: 3–7 days.

- Hand-finished crystal and bespoke designs: 7–14 days.

Local suppliers advertising laser engraved trophies Sydney usually provide express or insured courier options for metropolitan delivery — an important consideration when events are scheduled tightly.

Practical customisation ideas that make awards memorable

Personalisation can make a trophy a lasting keepsake. Consider:

- Team logos or mascots vector-etched on medals and shields.

- Photo engraving for milestone awards.

- Reverse-engraved inscriptions for private messages.

- Numbered limited editions for annual competitions.

- Layered materials with metal nameplates and inlaid acrylic.

These creative options are commonly requested when customers search for laser engraved trophies Sydney to make awards more meaningful.

Common ordering mistakes — and how to avoid them

Even the best laser systems can only do so much when the brief is incomplete. Avoid:

- Sending low-resolution artwork or screenshots.

- Choosing very thin fonts for small text.

- Skipping proofs for photo-based engravings.

- Assuming all materials behave the same without test samples.

Working with an experienced local supplier reduces these risks and ensures laser engraved trophies Sydney are produced right the first time.

Pricing guidance and budgeting tips

Factors affecting price: material choice, size, complexity of artwork, finishing (mounting, polishing, packaging) and order quantity. Tips:

- Standard acrylic awards are generally the most cost-effective.

- Bulk runs reduce per-unit cost due to steady machine runs.

- Crystal and custom multi-material assemblies cost more due to finishing.

- Photo engraving and special packaging increase labour.

Ask suppliers for tiered options (economy, standard, premium) so you can select an outcome that balances budget and presentation for your laser engraved trophies Sydney order.

Care and display: make awards last

Care instructions help recipients preserve awards:

- Acrylic & glass: use a soft cloth and mild cleaner; avoid abrasives.

- Timber: occasional polish with wood-safe products.

- Metal plates: Use a suitable metal polish and a soft cloth.

- Crystal: store in dust-free cabinets and handle by the base.

Providing care guidance with each delivery protects investment and maintains legibility for laser engraved trophies Sydney over time.

Case study: restoring a perpetual trophy with laser precision

A Sydney school commissioned a restoration of an old perpetual shield with missing plates and faded inscriptions. Using fibre engraving for replacement plates and CO₂ laser work for timber restoration, the workshop matched typefaces, re-etched years of names, and reassembled the shield. The outcome preserved heritage while renewing the trophy’s legibility and presence — a great example of how laser engraved trophies Sydney can support both conservation and modern presentation.

How to choose the right supplier in Sydney

Look for:

- In-house CO₂ and fibre capability.

- A diverse portfolio (schools, corporate, sports clubs).

- Transparent proofing and sample processes.

- Clear lead times and delivery options across Sydney suburbs.

- Local references, photos of finished pieces, and testimonial evidence.

Choosing the right partner increases the chance that your laser engraved trophies Sydney will arrive on time and exactly as envisioned.

Ordering checklist (quick)

- Choose material and finish.

- Provide vector logos and outlined fonts.

- Confirm text, spelling, and layout.

- Request a sample for new photo-based engraving.

- Allow time for proofing and delivery.

A short checklist prevents mistakes and keeps your project on schedule, especially during peak award seasons when demand for laser-engraved trophies Sydney is high.

The Science Behind Laser Engraving

To understand why it surpasses traditional engraving, it helps to know how laser engraving works.

A laser beam is focused onto a material, creating intense heat that causes the surface to melt, vaporise, or oxidise. Unlike manual tools, the laser doesn’t touch the material—it’s a contactless process, ensuring zero wear and tear.

In the case of laser engraved trophies Sydney, this means:

- Uniform designs with consistent depth.

- Ability to reproduce logos, signatures, or intricate artwork.

- Permanent results that don’t fade or peel, unlike paint or surface coatings.

Sydney businesses and event organisers particularly value this because logos, brand marks, and award titles often need to be replicated perfectly across multiple trophies.

The Role of Laser Engraved Trophies in Sydney’s Culture

Sydney is a vibrant city of achievements—from corporate excellence awards to school prize-giving ceremonies, local sports tournaments, and charity galas. Each event seeks a way to celebrate milestones in a meaningful, lasting form.

Laser engraved trophies have become the preferred choice because they:

- Capture Sydney’s multicultural identity with customised text and symbols.

- Support corporate branding with sharp, flawless logos.

- Offer flexibility in design, ensuring trophies are unique to each event.

Whether it’s a high school rugby final, a multinational company’s annual awards night, or a local art competition, laser engraved trophies Sydney provide a modern standard of recognition.

Corporate World: Professional Recognition

Sydney’s business hub thrives on acknowledging achievements. Law firms, tech startups, and global corporations host recognition ceremonies where trophies must reflect prestige and quality.

Laser engraving enables:

- Consistent branding with company logos.

- Personalised messages for each recipient.

- A professional look that reinforces corporate values.

For businesses in Sydney, these awards aren’t just decorations—they’re symbols of motivation, loyalty, and corporate culture.

Sports and Community Events: Lasting Legacy

Sports have deep roots in Sydney, from rugby and cricket to swimming and athletics. Traditional engraved trophies often wear down with time, making details unreadable. Laser engraving solves this problem by producing long-lasting inscriptions that resist fading even after decades.

This permanence is vital for clubs that want to preserve history. A junior league team’s yearly championship trophy, for example, can showcase engraved names for generations without losing clarity.

Case Study: A Sydney Corporate Awards Night

Consider a Sydney-based tech company hosting its annual innovation awards. With over 300 employees, they needed a large batch of trophies engraved with both the company logo and personalized recipient names.

Using traditional engraving, this would have taken weeks, with inconsistencies between trophies. Laser engraving, however, enabled all trophies to be completed within days, with perfect uniformity across the batch.

The result? A flawless ceremony where every recipient received a polished, professional-looking award—all aligned with the company’s branding.

Why Laser Engraving Will Continue to Dominate

Laser engraving isn’t just a passing trend—it’s becoming the industry standard. From its unmatched precision to its sustainable benefits, it clearly demonstrates why organisations are moving away from traditional methods.

For Sydney, a city that thrives on celebrating excellence, laser engraved trophies Sydney represent more than awards. They are a fusion of tradition and technology, capturing both the honour of recognition and the forward-looking spirit of the city.

Engraving has always been about preserving achievement in a physical form. But in Sydney today, traditional methods can no longer meet the demand for precision, speed, and sustainability. Laser engraving answers this need with flawless detail, durability, and creative freedom.

From boardrooms to sports fields, from classrooms to charity galas, laser engraved trophies Sydney are the future of recognition. They embody craftsmanship, innovation, and permanence—all while aligning with the values of modern Sydney.

As events continue to grow in scale and importance, it is clear: when it comes to engraving, the laser always outshines the chisel.

Read more : S.S. Rajamouli’s Movies: A Journey Through Epic Storytelling and Cinematic Mastery